Whether remodeling an older home or building new, you will need to choose the right flue liner material for safety and performance. Clay and metal liners each have pros and cons to weigh. This guide outlines the maintenance requirements, installation process differences, lifespans to expect, and cost factors involved with both traditional clay as well as modern stainless steel or aluminum alternatives.

The purpose of a chimney flue liner is to provide a safe, protected passageway for exhaust and smoke to efficiently vent from a fireplace or wood-burning appliance up through the chimney structure. By lining the inside of the flue with a corrosion-resistant material like clay or metal, it forms a smooth interior surface that helps pull combustion gases swiftly upwards and out of the home. A properly installed liner also isolates these hot fumes from direct contact with surrounding chimney materials like masonry, reducing fire and chemical leakage risks over time.

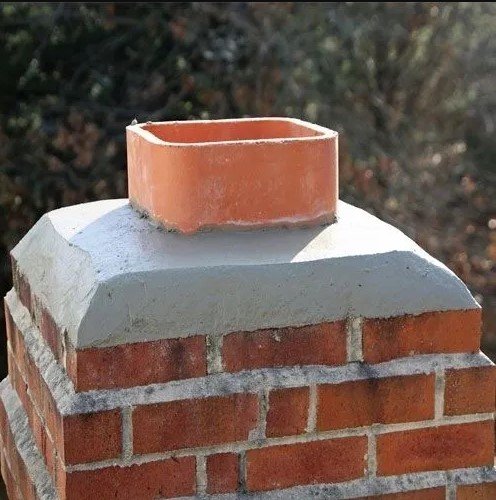

Clay chimney liners are one of the most traditional types of liner. Made of durable clay materials like terra cotta or fireclay, clay liners have been used for centuries. However, today there are really only two main types of clay liners still used – clay tile liners and cast-in-place clay liners.

Metal chimney liners provide durable, modern alternatives to traditional clay liners. The most common types of metal liners are made from stainless steel or aluminum.

Both stainless steel chimney liners and aluminum liners are manufactured as rigid tubing that fits securely inside the chimney.

Traditional installation of clay tile or cast-in-place clay chimney liners requires the expertise of a chimney specialist. It is generally a multi-day process that necessitates setting up scaffolding or safely maneuvering heavy lifting equipment inside the chimney flue. Clay liner tiles must then be individually stacked, leveled, and mortared into place from the bottom up by experienced masons.

Any errors in the installation process could compromise the integrity and safety of the clay flue liner over time. Given the intricate work, time demands, and safety precautions involved, most homeowners choose to leave the complex installation process to trusted professionals at a masonry contracting firm.

Modern metal flue liners like stainless steel are specifically engineered for quicker, easier installation compared to clay. Sections of the pre-formed rigid tubing simply need to be lowered into the chimney and connected together from the top down. No wet mortar mixing or waiting for drying time is required.

The rigid structure of metal means it holds its shape securely during installation without leveling or reinforcement. For most chimneys, a qualified professional can install a metal liner in just a day or less.

Traditional clay chimney liners like terra cotta or cast-in-place varieties will typically last around 20-25 years with proper care and maintenance. However, clay is porous and will gradually deteriorate faster over time due to factors like condensation, creosote buildup, or cracks from temperature cycling. Eventual replacement is inevitable as clay will eventually begin to flake or fail structurally.

Metal chimney liners are engineered to withstand corrosion, warping, and damage much longer than clay options. When professionally installed, a quality metal liner can reliably function for 25+ years with minimal care needed. Their non-porous construction makes them resistant to issues like condensation buildup or cracks over decades of use.

Clay chimney liner materials have lower start-up costs than metal options.

However, factoring in the intensive multi-day installation process, total labor costs for clay installation can easily exceed its material cost. Additionally, the shorter lifespan and eventual need for full replacement means higher long-term costs compared to durable metal liners.

Considering metal liners can provide safe, efficient venting for 50+ years with minimal upkeep, their operational cost over decades ends up much lower.

While clay chimney liners are effective non-combustible insulators, they lack the durability and corrosion resistance of metal over decades of high-heat use. Over time, microscopic cracks or incomplete seals could potentially allow dangerous flue gases to escape or creep into surrounding combustible areas.

The heat conductivity and non-porous construction of stainless steel and aluminum chimney liners make them highly resistant to thermal shock or cracking. This allows metal liners to maintain a secure barrier against exhaust gas leaks or external fires far longer than brittle clay materials.

Atlantic Brick and Stone is the most trusted name in chimney services in Fredericton. Our technicians can inspect, clean, reline, or repair any chimney or fireplace issues.

We offer a free estimate and warranty on all of our work. Customers can feel confident choosing Atlantic Brick & Stone for their chimney needs. We will guide homeowners to understand the condition of their chimney and which liner material will be the best option to maintain safety, efficiency, and reliability according to each individual situation.

The average lifespan of a chimney liner is 20-30 years, depending on the material and usage. Clay liners typically last 20+ years, while stainless steel liners can last up to 25+ years. Regular inspections by a professional can determine when replacement is necessary.

Minor cracks or damage to a clay chimney liner can sometimes be repaired with refractory mortar or sealant. However, if the damage is extensive or the liner is old, replacement is often the safer and more cost-effective option.

GET STARTED

Create stunning structures with our residential and commercial masonry services in Fredericton. From meticulous designs to the completed build, our process is professional and rewarding, and we can’t wait to build your dream with you.

Atlantic Brick and Stone, one of the best masonry contractors in Fredericton, NB

Contact

8 Muskie Street, Lower Kingsclear, New Brunswick E3E 0E7, Canada