4 popular types of masonry walls

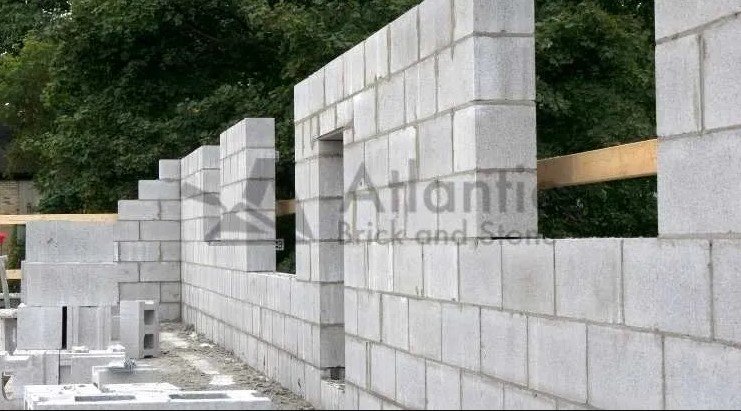

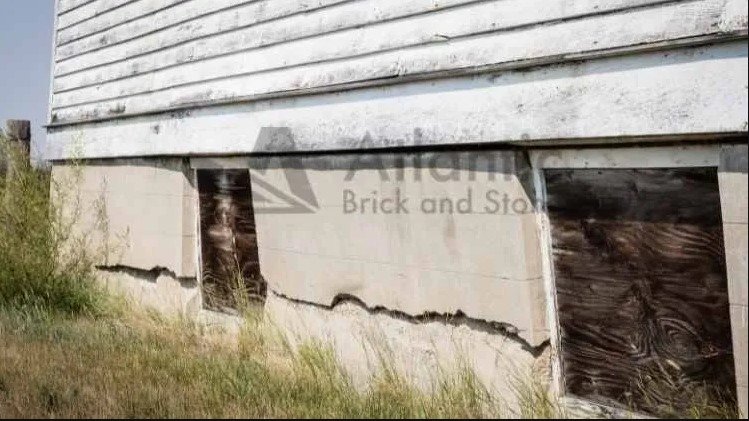

4 popular types of masonry walls Masonry walls are great for the home because they provide a barrier against the weather, sound, and to some degree, fires. They can also be made from many different types of materials for different purposes. In this article we will discuss 4 most popular types of masonry walls. Masonry Walls Masonry walls are made from stone brick concrete blocks. They’re commonly used as a protective wall in residential and commercial construction, but they can also be used to create a decorative facade. A masonry unit works on various projects and contributes to various purposes. Depending on the job, some may make walls for house construction, some may make barriers for property lines, and some may create house walls for structural use. Load Bearing Walls Load bearing masonry walls are a method of constructing a building’s exterior by using brick, stone, or other strong material to provide structural support for the building. They are typically made of hollow blocks that have been either cast from concrete or carved from stone. This process is significantly cheaper than creating a steel frame and replacing it with solid masonry. Load bearing walls perform a vital function in large buildings by holding up the roof. These walls are usually constructed of material that is strong enough to support the weight of the roof. These types of walls are also used along with other structural components like steel beams to hold up taller buildings. These walls are commonly found in residential constructions, such as houses, apartments, and condos. Reinforced Masonry Walls Reinforced masonry walls are a cost-effective option for securing residential homes. The process of installing these walls takes between 7 and 10 days, depending on the size of the house. For smaller homes, this process should take no more than 4 days. These walls are designed to be fitted with steel plates which offer greater protection against burglary attempts. Steel reinforcement is also used in the joints of the mortar to provide strength against pressure from outside forces. A reinforced masonry wall is made of a concrete core with brick or stone on the outside. The concrete is usually poured in sections and then cured, which means that it sets and becomes hard. The bricks or stones are laid on top of the concrete, and cement mortar is used to fill in the gaps between them. This creates a strong barrier that can withstand both high winds and earthquakes. Hollow Masonry Walls Hollow masonry walls are walls that are partially hollow. They’re most commonly seen in areas that have high humidity or lots of rain. These types of walls are made from stone, brick, or concrete. Hollow masonry walls are built for a variety of reasons. They are often used to make the walls of buildings more structurally sound, or they can be used as insulation against heat and cold. Hollow masonry walls are also sometimes used to make the structure more resistant to earthquakes. Composite Masonry Walls Composite masonry walls are composed of both brick and stone. The bricks act as a thermal mass to help regulate the temperature inside the building. They also give the wall more strength than it would otherwise have. Composites are composed of two masonry wythes that are bonded to each other. There are two ways of building a wall: one could be brick or stone masonry, while the other could be hollow bricks. Wythes are vertical masonry sections of one unit of thickness. Typically, these wythes are interconnected either through horizontal joint reinforcement or through steel ties. The purpose of composite masonry walls is to provide a durable and economical structural system for the exterior of a building. These walls consist of two or more layers of brick or block, with a layer of insulation in between, and sometimes a water-resistant membrane on the exterior. Get Your Brick, Stone or Block Walls Estimate Online Now! 506-304-0771 atlanticbrickandstone@gmail.com Request an Estimate