What You Need to Know About Masonry Construction?

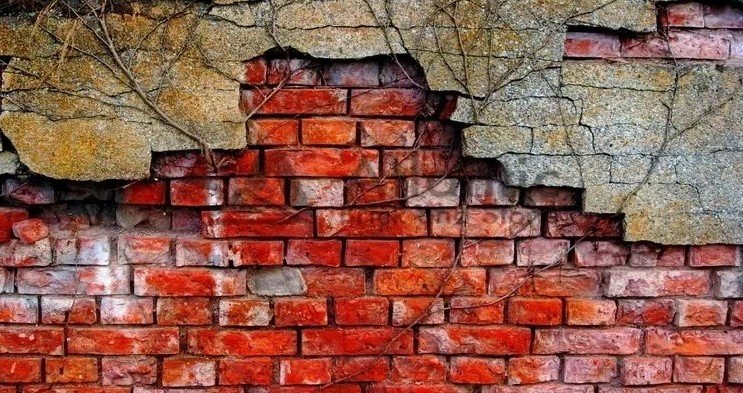

What You Need to Know About Masonry Construction? Masonry construction is a popular choice for many people looking to build or improve their homes. There are many benefits to masonry construction, including its durability and its aesthetic appeal. If you’re considering masonry construction for your next home improvement project, here’s what you need to know. What is Masonry Construction? Masonry construction is one of the oldest and most popular types of construction. Masonry is made up of bricks, stones, or concrete blocks that are held together with mortar. This type of construction is strong and durable, and can be used for both residential and commercial buildings. It is a good choice for many projects because it is fire resistant and soundproof. Masonry construction is well suited for both new construction and renovations. When properly constructed, masonry buildings can last for centuries. In fact, many of the world’s most iconic structures are made of masonry. Materials Used in Masonry Construction Masonry construction has been around for centuries, and the use of bricks, stone, and blocks in construction is a tried-and-true method. While the materials used in masonry construction have changed over the years, the basic principles have remained the same. Bricks Bricks are the most common masonry construction material. Bricks are made from clay or shale that is fired in a kiln. The firing process gives bricks their characteristic red color. They are available in a variety of sizes and shapes. Brick is a durable construction material that is resistant to fire, weathering, and pests. Stone Stone is another common masonry construction material. Stone can be natural or man-made. Natural stone is quarried from the earth and then cut into the desired shape and size. Man-made stone is created by crushing natural stone and then mixing it with a binding material such as Portland cement. Stone is available in a variety of colors, textures, and sizes. Stone is a durable construction material that is resistant to fire, weathering, and pests. Blocks Blocks are another common material used in masonry construction. Blocks are made from concrete, and are available in a variety of sizes. They are typically laid in a mortar bed, and are held together with mortar joints. Mortar Mortar is a binding material used to hold bricks, stones, or blocks together. Mortar is made from a mixture of cement, sand, and water. It can be applied wet or dry. Mortar is a versatile construction material that can be used to create a variety of architectural styles. Concrete Concrete is a common type of masonry construction material. Concrete is made from a mixture of cement, aggregate (such as sand, gravel, or crushed stone), water, and chemical admixtures, and is mostly used in the foundation of the building. The Benefits of Masonry Construction Masonry construction has many benefits that make it a popular choice for both home and commercial building projects. Some of the main advantages of masonry construction include: Durability: Masonry is a very durable material that can withstand a lot of wear and tear. It is also resistant to fire and pests, making it a good choice for both home and commercial construction. Design flexibility: Masonry can be used in a variety of different ways to create different looks and designs. This makes it a good choice for both home and commercial buildings. Environmentally safe: Masonry is a natural material that is not harmful to the environment. It is also recyclable, making it a good choice for any type of construction. Better insulation: Masonry is a good insulator, keeping both heat and cold out of a building. This makes it a good choice for every construction project. Structural integrity: Masonry is a strong material that can support a lot of weight. This makes it a good choice for both commercial and residential projects. The Drawbacks of Masonry Construction Masonry construction has many benefits, but there are also some drawbacks to consider. One of the biggest drawbacks is that masonry is a moisture absorber. This can lead to color deterioration and even mold and mildew growth. Another downside to masonry construction is that it can be quite expensive. The materials and labor required for masonry construction can add up quickly. If you are on a tight budget, masonry construction may not be the best option for you. If you are willing to put in the time and effort, masonry construction is one of the best options due to numerous and long-lasting benefits. Conclusion Masonry construction is a great way to build your home. It is durable, fire resistant, and can withstand high winds. Masonry construction is also energy efficient and can help you save money on your heating and cooling bills. With its many benefits, it is no wonder this method is still popular today. If you are thinking of building with masonry, be sure to do your research and hire a qualified masonry contractor to get the job done right. Get Your Residential or Commercial Building Construction Estimate Online Now! 506-304-0771 atlanticbrickandstone@gmail.com Request an Estimate