Steps to Protect Your Driveway and Landscaping During Snow Plowing

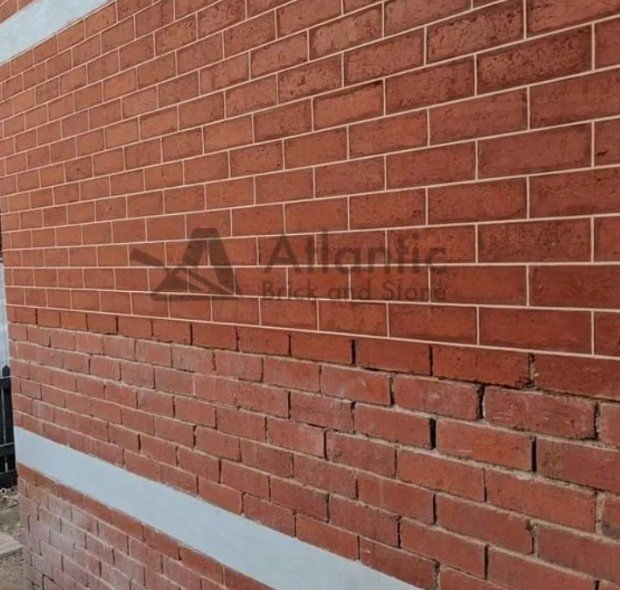

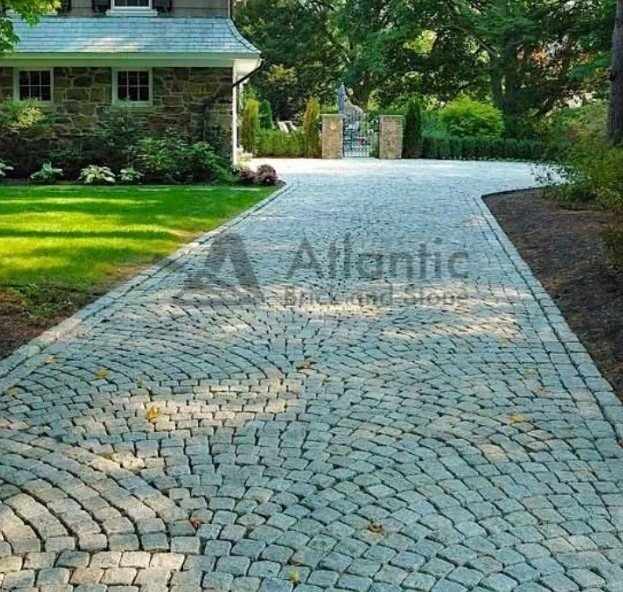

Steps to Protect Your Driveway and Landscaping During Snow Plowing Winter in Fredericton brings heavy snowfall, making snow plowing essential for property maintenance. Your driveway and landscape require specific protection measures during snow removal. Installing reflective markers, sealing your driveway surface, and proper plant trimming create a foundation for safe snow clearing that preserves your property’s integrity throughout the season. Preparation before the snowfall Mark your driveway Your first defense against snow plow damage starts with proper marking. Place reflective markers along your driveway edges every 6-8 feet. These markers serve as visual guides for plow drivers, helping them navigate your driveway safely in low visibility conditions. Choose markers that stand at least 3 feet tall to remain visible above accumulated snow. Trim back plants Before winter sets in, inspect your landscape for any vegetation near your driveway. Prune branches hanging over your driveway and trim shrubs that might interfere with snow removal. This preventive measure protects both your plants and the plow blade from potential damage. Seal your driveway A sealed driveway provides better protection against the effects of snow and ice. Apply a quality sealant to your pavement before temperatures drop. This creates a barrier that prevents water from seeping into cracks and causing damage through freeze-thaw cycles. Clear debris Remove any portable items from your driveway and walkways. Garden hoses, toys, and decorative elements can become hidden under snow, risking damage to both the items and snow removal equipment. Hire a reputable snow removal company Find a Fredericton snow removal company you can trust, that involves following steps: Ensure the snow removal service carries adequate insurance to protect against potential liabilities. Inspect the state of their equipment to verify it is well-maintained. Check references in your area to assess their reliability and service standards. Scrutinize their contract to ensure it clearly specifies roles and expectations for winter maintenance. During snow plowing operation Give clear guidelines to your plow driver Creating clear guidelines with your snow removal service helps prevent potential damage to your property. Start by walking your property with the plow driver, highlighting sensitive landscape features that need special attention. Show them where snow can be safely piled without damaging your lawn or plants. Discuss any specific concerns about your driveway surface, such as recent repairs or delicate materials. This upfront communication establishes clear expectations and helps protect your investment in your property. Monitor the plowing Taking an active role in supervising snow removal protects your property interests. Notice how the plow operator maintains proper blade height to avoid scraping your driveway surface. Watch their technique as they maneuver around landscape features, ensuring careful navigation around corners and edges. Pay attention to where they pile snow, confirming it’s placed in designated areas away from structures and sensitive plantings. Your attention during the process helps maintain quality control and prevents potential issues. Clear snow promptly Swift snow removal serves as your best defense against winter damage. When snow sits too long, it compacts and bonds with your driveway surface, making removal more difficult and potentially damaging. Regular clearing prevents ice formation that could crack or heave your pavement. By maintaining consistent snow removal, you reduce the stress excessive weight places on your driveway and protect its structural integrity throughout the winter season. After snow plowing Inspect your driveway and landscaping Following each snow removal service, conduct a thorough property inspection. Look for any fresh pavement scratches or cracks that might have occurred during plowing. Check your lawn edges where the plow blade may have made contact. Examine landscape elements near the driveway for signs of impact or stress. Recording and reporting issues promptly to your snow removal company ensures quick resolution and prevents further damage. Remove salt and ice melt Protecting your property from de-icing materials requires prompt attention. Remove excess rock salt or calcium chloride from your surfaces to prevent chemical damage. Once temperatures rise above freezing, rinse your driveway and walkways thoroughly to remove residual chemicals. For areas with sensitive plants or newer concrete, consider using alternative de-icing products that cause less damage while maintaining safety. Key points Remember these key points: Mark driveway and landscape boundaries clearly Choose reputed snow removal company Maintain regular communication with plow drivers Use appropriate de-icing materials Address issues promptly Keep documentation of any damage Hire Atlantic Brick and Stone for safe snow plowing service Atlantic Brick and Stone delivers safe snow plowing services in Fredericton, combining quality with affordability. Our experienced plow operators use modern equipment to protect your driveway and landscape while efficiently clearing snow. Our company provides 24/7 emergency response, ensuring your property stays accessible throughout winter weather events. Our comprehensive service packages include both regular maintenance and on-call snow removal, making us a trusted choice for residential and commercial property owners seeking professional snow management without breaking the bank. With our strong reputation for property protection and prompt service, we have become number one contractor for winter maintenance needs in the Fredericton area. FAQs about snow plowing for driveways and landscape How can I properly mark my driveway for snow plowing? To mark your driveway for snow removal, use tall, brightly colored markers or stakes that are easily visible above snow levels. Place them along the edges of the driveway at regular intervals to guide the snowplow operator and protect your landscaping. Ensure the markers are securely anchored to withstand wind and heavy snow. What is your specific plowing techniques to protect my property? Our plow operators angle plows away from landscaping and avoid scraping too close to the driveway’s edges or delicate areas. How you can protect fragile surfaces like pavers or stamped concrete? We may use snow blower to clear snow from delicate surfaces without scratching or cracking them. Get Your Driveway snow plowing Estimate Online Now! 506-304-0771 atlanticbrickandstone@gmail.com Request an Estimate